Our Process

Discover the Precision, Passion, and Process Behind Every Slab.

Experience the precision and craftsmanship behind every slab—meticulously extracted, processed,

finished, and customized to perfection, ensuring unmatched quality from source to site.

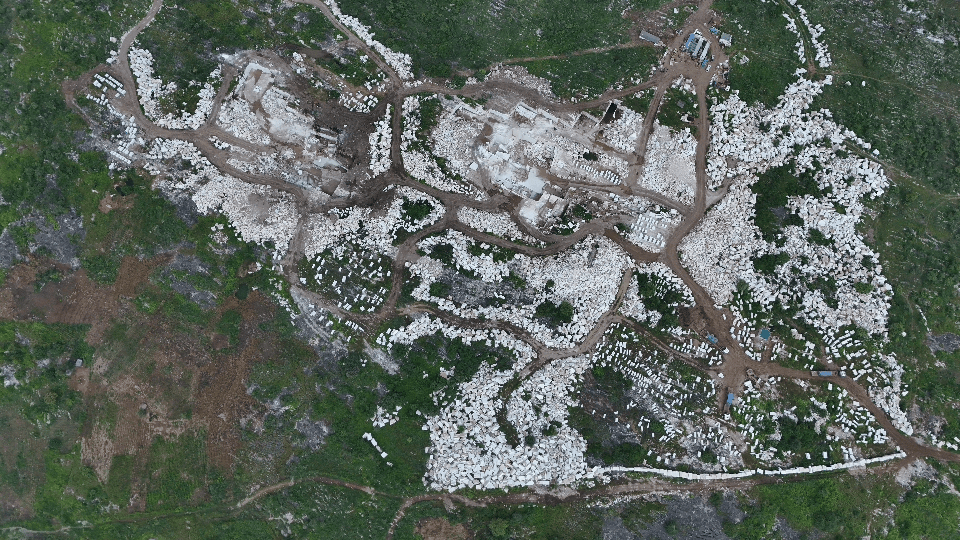

At A-Class Overseas, our story begins in the mineral-rich belts of Zambia and Tanzania, where we own and operate our quarries. This control allows us to handpick blocks with absolute precision, ensuring authenticity and consistency from the Source. Every extraction is a blend of science and respect for natural stone—guided by experts who study each block’s formation before it’s chosen.

Before the blocks move to our Indian facility, a dedicated selection phase ensures that every customer purchasing raw blocks receives only the finest grade. As quarry owners, we supply premium marble blocks directly to global buyers who require consistent colour, stable structure, and reliable repeatability. Each block is graded, documented, and stocked separately based on geological attributes, making it easy for architects, factories, and distributors to choose exactly what they need.

The marble blocks begin their journey from Africa to our advanced facility in Kishangarh, India. Transport is meticulously planned to safeguard the stone’s structural integrity. We use reinforced loading systems, anti-vibration handling, and secure packing to ensure the blocks remain unaffected during long-distance movement. Each shipment is monitored end-to-end, guaranteeing timely and damage-free arrival.

Upon arrival, the blocks undergo comprehensive preparation to enhance stability and ready them for precision cutting. They’re cleaned, dressed, and meticulously reinforced. Dust is removed through grinding and air-blowing, followed by the application of fiberglass netting. Epoxy (Tenax) is injected via pipes and vacuum-treated to penetrate deeply into natural micro-fissures, sealing and strengthening the block from within. This treatment ensures flawless slabs during cutting.

Reinforced blocks are cut into precision slabs using high-performance gangsaw machines. Each slab meets international standards of 18+ mm or 20+ mm thickness. Post-cutting, Prometec robotic systems take over for structural reinforcement. Slabs are heated to remove moisture, net-backed for strength, epoxy-coated, cured, reversed, cleaned, and finely ground using water jets to achieve uniformity.

Every slab undergoes a multi-level quality check focused on strength, colour consistency, structural stability, and overall visual clarity. Our finishing team enhances each slab through polishing, honing, brushing, or texturing based on the design requirement. The result is a slab that is not only structurally superior but visually refined and globally benchmarked.

Once perfected, the slabs are sealed and securely packaged for dispatch. A protective sealant enhances durability and shields the stone during handling. Eco-friendly, impact-resistant packing materials prevent cracks, chips, or abrasions. Logistics are coordinated based on destination, ensuring smooth movement to domestic and international sites with complete tracking.

Over 50 years of Sustainable

Architectural Excellence

At A-Class Overseas, we embrace innovation by integrating the latest technologies in mining, processing, and finishing. Our tech-forward approach ensures superior quality, precision, and sustainability—meeting the evolving demands of modern architecture with timeless elegance.

Tons Production Capacity

Hectares Extraction Unit

Diamond Wire Saws

Showcasing timeless marble artistry, elegance, and exceptional craftsmanship.

A-Class Overseas is a proud extension of the A-Class Group, building on over five decades of leadership and expertise in the marble and natural stone industry. Specializing in sustainable mining and global supply of premium natural marble and stone, A-Class Overseas operates four fully operational quarries in Zambia and Tanzania, and a processing unit in Kishangarh, India, ensuring complete control over extraction, processing, and quality management. This enables us to deliver the finest materials for both domestic and global markets with consistency and reliability. Committed to responsible mining practices and innovation, A-Class Overseas shapes inspiring spaces by providing high-quality marble and stone solutions that transform architecture into timeless experiences.

Step inside our world of craftsmanship, collaboration, and celebration.

Five decades of passion, precision, and pursuit of perfection. Shaping marble into timeless symbols of excellence.

Owning the source, mastering the craft — excellence begins where our quarries stand.